DoE requirements. It's also built with tomorrow’s technology advancements in mind, so you and your customers are ready for whatever comes.īuilt for the harshest industries and applicationsĪ wide range of industries already trust their operations to Siemens severe-duty motors - from oil and gas, petrochemical, pulp and paper, and mining, to food and beverage, water and wastewater, minerals, and more. At 125 - 800 horsepower and 444 - 5013 frame size, it delivers maximum efficiency without complications - not only meeting but exceeding NEMA Premium and U.S. The footing works for the vast majority of retrofits and a broad selection of options makes custom orders a thing of the past, allowing for optimal performance in diverse operating conditions. The SIMOTICS NEMA SD200 motor from Siemens combines flexibility, performance and efficiency to meet virtually any customer need. Inpro/Seal® bearing isolators are standard on both ends Single shielded bearings and V ring slingers are used for optimum bearing protection against contaminants.

#Siemens vdo lower stator plus#

A wide selection of options, among them IP56 ingress protection, encoders, brakes and blowers, plus other QuikMOD modifications provide higher flexibility and reliability in diverse operating conditions. All SD100 IEEE841 severe duty motors are equipped with drive end and opposite drive end Inpro/Seal® bearing isolators. They are designed and manufactured to meet or exceed NEMA Premium® efficiency (MG1 Table 12-12) higher efficiency is available on many sizes with the optional copper rotor. Built for long, trouble-free life, they are backed up by a 5-year warranty.Īll SD100 IEEE841 motors are inverter duty and have their VFD ratings right on the nameplate. Users in these industries trust their operations to the SD100 to power fans, compressors, pumps, conveyors, hoists, winders and many more applications in the toughest environments day in / day out). First used in petroleum and chemical applications, it is also specified in other industries such as pulp and paper, mining, food and beverage, water and wastewater, minerals and more. The SIMOTICS SD100 IEEE841 severe duty motors are designed and built to the very stringent IEEE 841-2009 standard for long, trouble-free life in harsh environments. Siemens motors are available with a wide variety of QuikMOD modifications and custom designs to meet specific motor needs Inpro/Seal® bearing isolators are available on both endsĪ specially formulated, high temperature tested, polyurea-based grease is used to provide more than four times the lubrication life of other greasesĬast iron construction, polycarbonate fan, zinc-plated hardware, epoxy enamel paint and stainless steel nameplate resist rust and corrosion. Cast Iron fan covers are standard for all frame sizes Its low-inertia design reduces windage losses, improves airflow, reduces noise and provides dependable cooling.

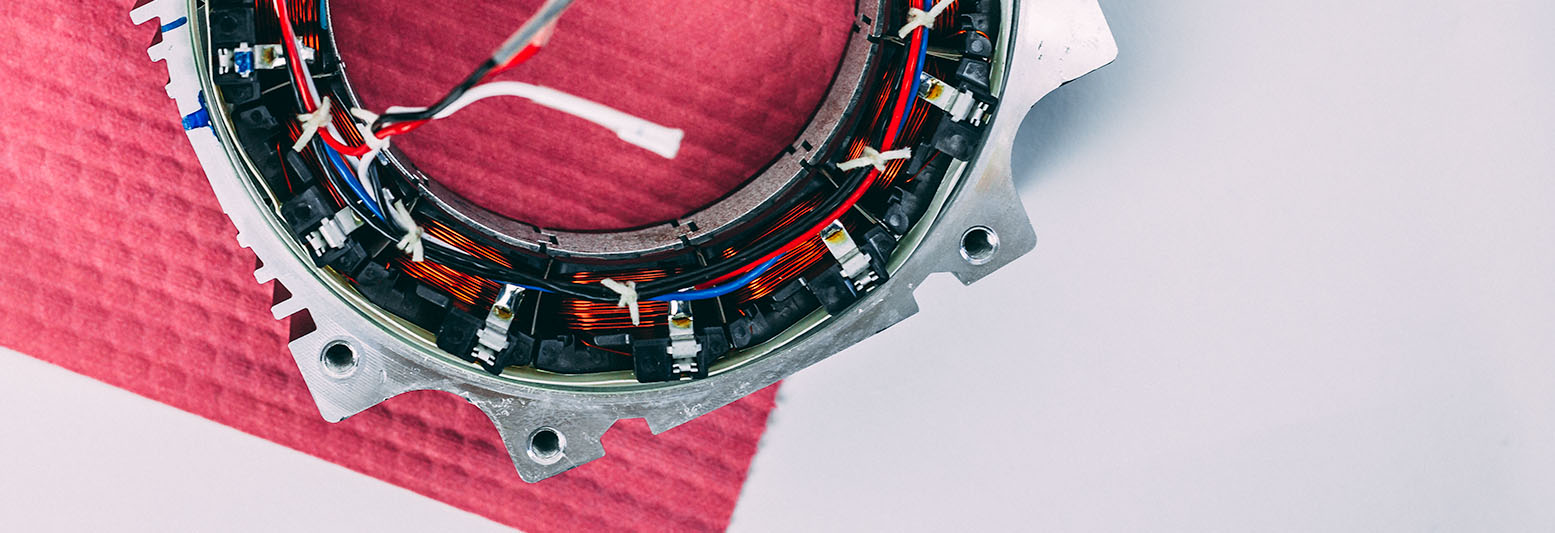

All windings are tested for CIVĪ non-sparking, bi-directional fan is locked and keyed to the shaft. This insulation system meets or exceeds NEMA MG1 2014 Part 31 making the motors suitable for variable speed drives in constant torque (4:1) and variable torque (20:1). The varnish system ensures maximum winding penetration to provide protection from moisture, corrosion and electrical shock. The proprietary Class F non-hygroscopic insulation system with NEMA Class B temperature rise provides an extra margin of thermal life. The stator is manufactured with premium electrical C5-grade steel laminations and copper electrical magnet wire that furthers the reduction of losses Each die cast aluminum rotor assembly is dynamically balanced for extended bearing life and includes a high-strength carbon steel (C1045) shaft for maximum rotor performance. These characteristics plus high strength zinc-plated hardware, epoxy paint and stainless steel nameplates provide exceptional structural integrity and corrosion resistance and make them ideal for severe duty applications in harsh environmentsĪ unique offset rotor bar design provides improved efficiency, while larger bars and end rings reduce resistance for lower rotor losses.

The terminal box features a neoprene gasket and includes a heavy duty ground lug and clearly and permanently marked non-wicking leads.

The SIMOTICS SD100 frame, end shields, fan guard and easy-to-access diagonally split, oversized terminal box are all cast-iron.

0 kommentar(er)

0 kommentar(er)